University of Tennessee-Oak Ridge Innovation Institute

UT-ORII was created to facilitate collaborative and convergent research and expand the pool of science, technology, engineering, and mathematics (STEM) talent to meet the needs of the nation and the state of Tennessee. Close collaboration between the PIs and Oak Ridge National Laboratory (ORNL) staff facilitated through UT-ORII creates opportunities to leverage the strengths in materials research at ORNL in the Materials Science and Technology Division, the Spallation Neutron source, the Center for Nanophase Materials Sciences, the High Temperature Materials Laboratory, the High Flux Isotope Reactor, and others. UT-ORII administers the Student Mentoring and Research Training (SMaRT) summer internship program to partner with undergraduates from dozens of institutions across the country, including six strategically partnered historically Black colleges and universities (HBCUs) to train the next generation of scientists and engineers. We work with other UT-ORII faculty including Toby Nelson, Dustin Gilmer, and Zachary Sims.

Institute for Advanced Materials and Manufacturing

IAMM is home to core facilities accessible by UT faculty and staff that include the Advanced Photoelectron Spectrometer, Electromagnetic Properties Lab, Electron Microscopy Center, Diffraction Facility, Genomics Core, Polymer Characterization Lab, Micro-Processing Research Facility, Ion Beam Materials Laboratory, Molecular Beam Epitaxy, and MABE Maker Lab. There are also several laboratory spaces assigned to individual PIs offering other state-of-the-art instruments for materials characterization. Our primary collaborators at IAMM are Dayakar Penumadu and Rigoberto Advincula.

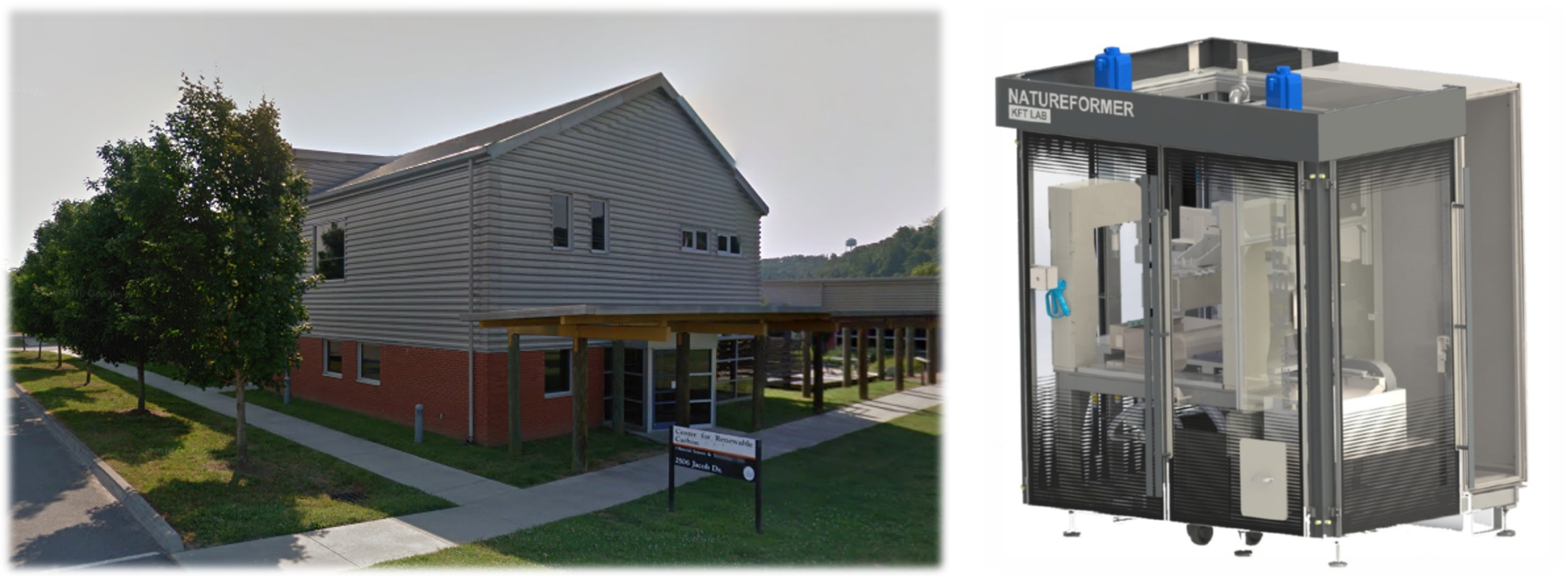

Center for Renewable Carbon

The University of Tennessee’s CRC has a wide range of equipment to support biomass preprocessing, grinding, chopping, pretreatment, fractionation, isolation, conversion, characterization, and chemical analysis for biobased fibers. The labs are equipped with a full complement of standard chemistry, biochemistry, biomass, and materials science equipment, instrumentation, and services. In addition to bio-based materials, the labs are equipped with polymer processing equipment such as a Kiefel Natureformer used to manufacture bio-based composites. Our primary collaborators at the CRC include David Harper and Mi Li.

Fibers and Composites Manufacturing Facility

The University of Tennessee’s FCMF focuses on comprehensive research and development to prototyping of advanced fiber reinforced plastics and composites. The core competency of the FCMF is in product and process development, characterization, modeling and simulation, and nondestructive evaluation of advanced thermosets and thermoplastic composites. The FCMF is led by Uday Vaidya.

Institute for Advanced Composite Manufacturing and Innovations

IACMI is a Manufacturing USA institute for enabling TRL 4-7 R&D and pre-commercialization support sponsored by the Department of Energy. IACMI has 130 plus member companies and has executed over 50 value-added projects for accelerating development and adoption of innovative manufacturing technologies for low-cost, energy-efficient manufacturing of advanced polymer composites for vehicles, wind turbines, compressed gas storage, aerospace, and industrial applications. As a public-private partnership, IACMI offers opportunities to directly interact with experts from material suppliers, part manufacturers, and system designers, ensuring that the sponsored research meets industry needs and encouraging the translation of technology from academia to industry via member companies including several start-ups. IACMI is led by CEO Chad Duty and CTO Uday Vaidya.

Oak Ridge National Laboratory

ORNL is the largest Department of Energy National Laboratory located just down the road from the University of Tennessee. Their mission supports scientific discovery, clean energy, and national security through a host of world-class scientific user facilities. The Manufacturing Demonstration Facility (MDF) is a laboratory consortium for accelerating manufacturing innovation for clean energy. We collaborate with members of the Composites Innovation and Sustainable Manufacturing Technologies groups.