Focus:

We seek to change the end-of-life and waste paradigms for fiber-reinforced composites by developing low-cost, high-performance composite materials with integrated functionality. Our current interests are in finding solutions to waste from composite structures such as aging aircraft and wind turbine blades, decreasing the energy usage and cycle time required for manufacturing advanced composites, and creating structural materials capable of functions such as damage sensing and stimulus response. The team works closely with other researchers at the University of Tennessee Fibers and Composites Manufacturing Facility (FCMF), Center for Renewable Carbon (CRC), and Institute of Advanced Materials and Manufacturing (IAMM), as well as the Institute for Advanced Composites Manufacturing Innovations (IACMI) and researchers at the ORNL Manufacturing Demonstration Facility (MDF).

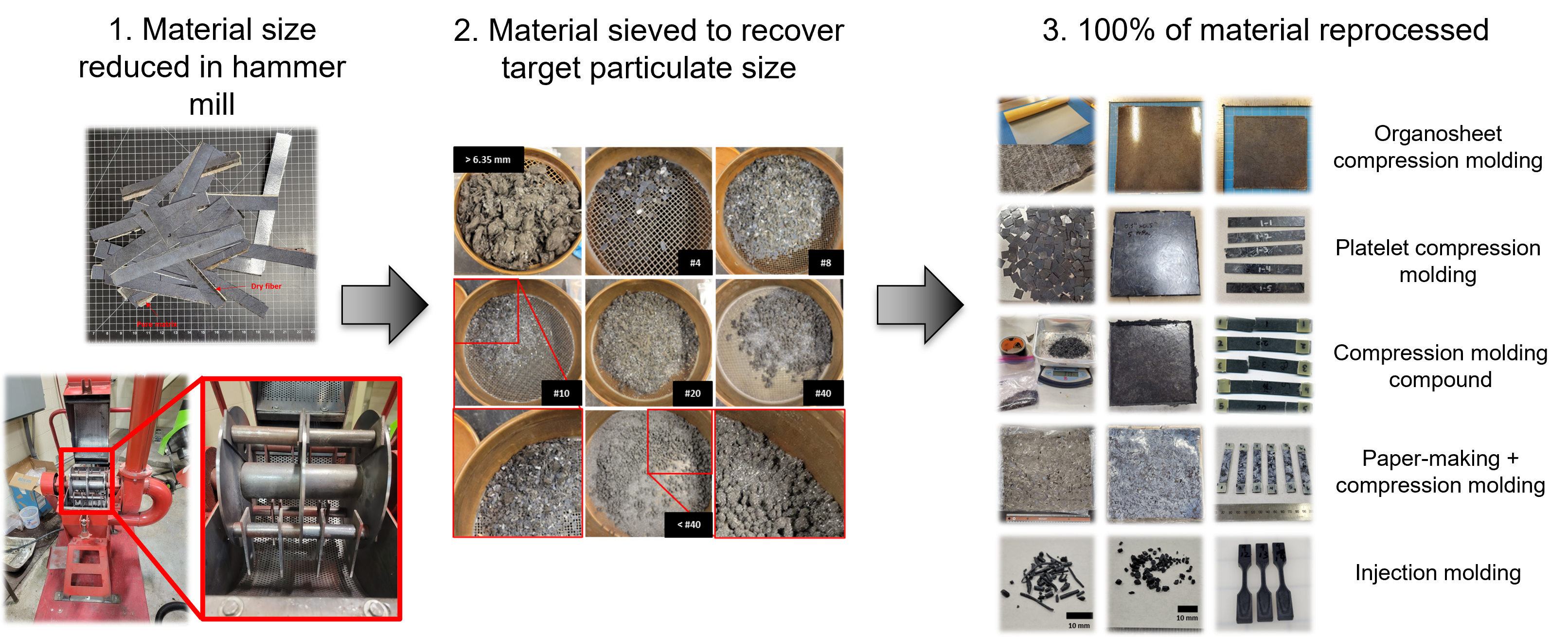

Zero-waste recycling of thermoplastic composites is possible. The properties are strongly dependent on the fiber length and the inhomogeneity associated with wider length distributions. By controlling these variables, we can produce higher performance recycled fiber composites and extend the number of future lifecycles. Read more at: https://www.nature.com/articles/s44296-024-00006-y.

Areas of current work:

Composites manufacturing, advanced materials, carbon fiber, additive manufacturing, recycling, natural fibers, hybrid materials, vitrimers, phase change materials, stochastic modeling, crashworthiness

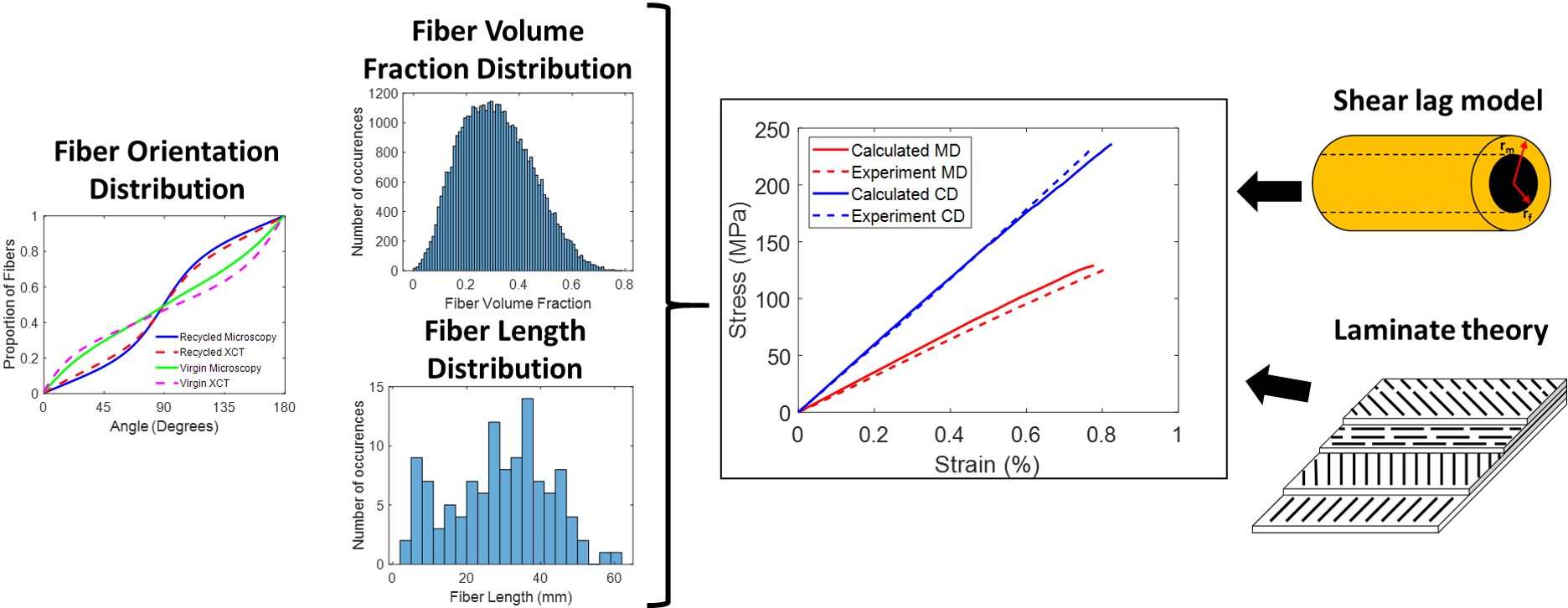

Simple homogenization techniques for performance prediction are inadequate. Capturing microstructural inhomogeneity enables accurate prediction of composite strength and stiffness. Read more at: https://doi.org/10.1016/j.compscitech.2021.108857.

Future Directions:

We are currently seeking graduate students interested in green chemistry resin development, materials circularity, multifunctional composites, and understanding the process/structure/property relationships dictating the behavior of composites at elevated strain rates and temperatures. Please reach out if you are interested in working with us!

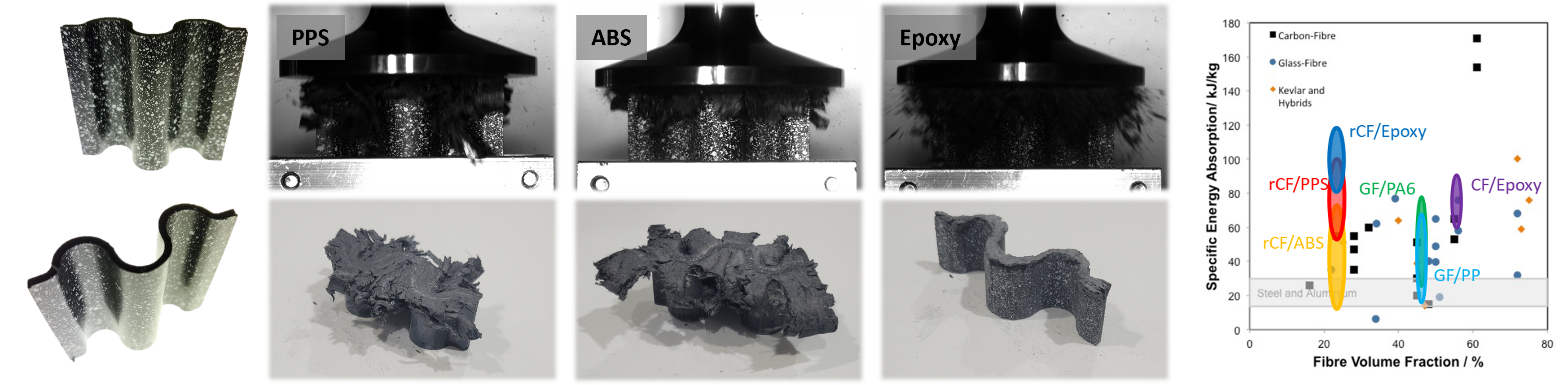

Recycled carbon fiber composites offer comparable or better energy absorption to continuous fiber laminates at nearly 50% reduction in fiber content. The resulting reduced mass, cost, and embodied emissions could have a substantial impact on the automotive industry. Read more at: https://doi.org/10.1016/j.compstruct.2023.116847.

Keywords:

Composites, carbon fiber, multifunctional materials, hybrid materials, rapid manufacturing, natural fibers, micromechanics